Ensure you know the torque specification.

Electrical bus bar torque specs.

3 9 16 lugs require a torque of between 20 and 30 foot pounds.

I was a young firefighter and licensed master electrician and i was fascinated with the array of investigative tools the marshal had at his disposal to determine causes of electrical failures.

Bus bar and terminal connections.

The required torque spec was 20 foot pounds 250 inch pounds.

Knowing required ampacity determine possible bus bar dimensions from the table.

Connections can create electrical noise power quality issues by vibrating and creating arc at the connection.

Use the torque specifications in.

Bolt size 5 8 11 1 2 13 3 8 16 1 4 20 torque pounds feet 55 70 35 50 20 30 5 7.

1 2 13 lug bolts should be torqued between a range of 35 and 50 foot pounds.

The dipole diode bus bar to bus bar connection is bolted with six m6 screws with a torque of 10 nm 5.

Tm 5 683 nawac mo 116 afjman 32 1083.

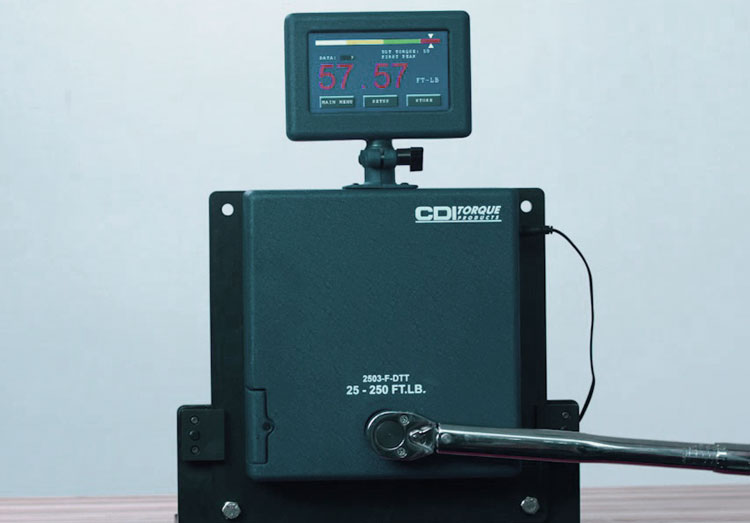

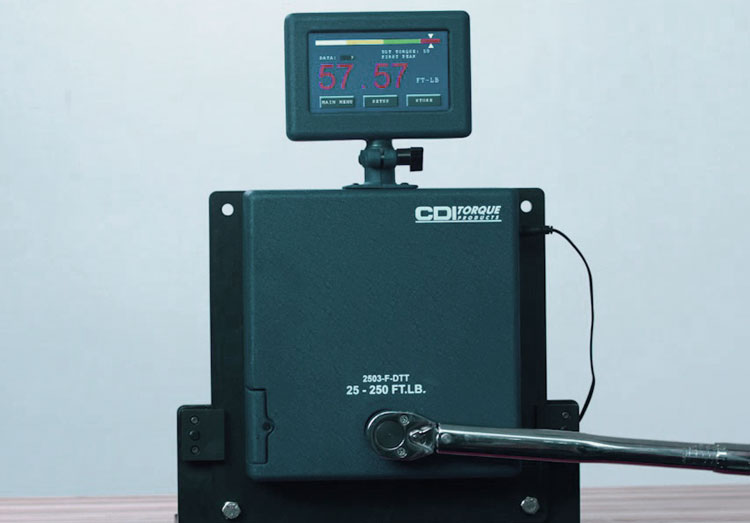

Ensure your electricians own and know how to use a torque wrench.

For 60 hz current table gives bus bar cross sections which will probably be large enough for ampacities within each range.

I ve seen bolts which were barely half their original diameter in the middle removed from bus joints.

89 600 mpa 172 400 mpa 517 000 to 620 500 mpa.

Then check table 1 to verify that size selected has the necessary ampacity.

Good2 depending on very good.

The nuts and bolts of any electrical system are the connectors which keep the current flowing.

The connections were tightened to only around 12 foot pounds 144 inch pounds.

3 9 16 lugs require a torque of between 20 and 30 foot pounds.

3 9 16 lugs require a torque of between 20 and 30 foot pounds.

Reduce torque by 20 when cadmium plated bolts are used.

Up facilities engineering electrical interior facilities.

Electrical conductivity 214 percent 100 percent by mass at 20 ec.

Electrical conductivity 62 percent 100 percent 12 percent by volume at 20 ec.

Have the bus bars cleaned annually with clean dry.

Thermal conductivity 218 391 59 8 w m k.

Assume that required ampacity is 185 amp at 30 c rise.

All of the major companies who manufacture electrical components have torque specifications for their equipment ask for it.

Torque can stretch the bolt past its elastic limit and cause failure.