This is basically a question of motor design there is no straightforward regular relationship between capacitance and the motor size in.

Electric motor capacitor size calculator for motors.

The capacitor size for an ac motor is calculated base on the amount of current required to start the motor.

Motor capacitors store electrical energy for the motor to use.

Wondering how a capacitor can be used to start a single phase motor.

Firstly you should know about on which type of single phase motor you want to calculate capacitor value.

Divide the start up energy requirement in joules of the motor by x to arrive at the capacitor size needed in farads.

An electric motor capacitor is a device that first stores then releases an electrical charge to help start an electrical motor starting capacitor or to keep it spinning run capacitor the electrical charge or potential energy stored in the capacitor is used to give a power boost to the motor to help it overcome inertia to start rotating.

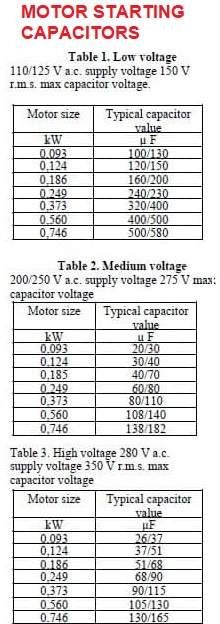

When install a motor using capacitor for starting or running methods we must sizing the rated of capacitor suitable with motor to get correct starting torque and avoid winding from overheating and can cause a damage.

A bad motor capacitor may cause starting problems or could shut off the motor while running.

This calculator is for educational purposes.

A damaged or burnt out capacitor may hold only a fraction of the energy needed for the motor if its capacitance is low.

If motor has centrifugal switch then it won t be a permanent split capacitor motor.

Three phase motors are widely used because they are reliable and economical.

Ac motor start capacitors provide a burst of energy to start motor rotation in small single phase ac motors such as those used to power fans and pumps.

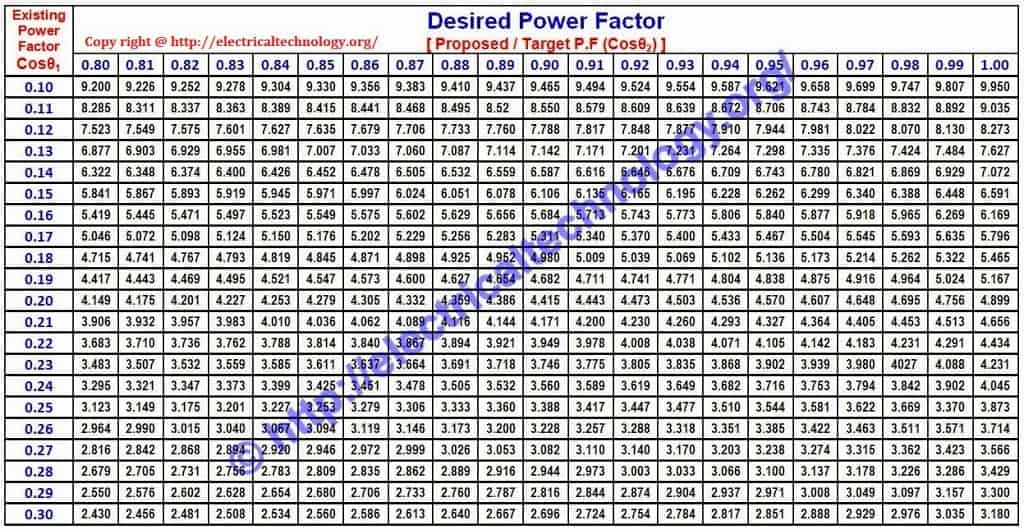

Calaculate power factor apparent power reactive power and correction capacitor s capacitance.

The higher the capacitance of the capacitor the more energy it can store.

The start up energy of the motor is found either in its documentation or written on the motor itself.

Click here to view a capacitor start motor circuit diagram for starting a single phase motor.

Ac induction motors also known as asynchronous motors use a rotating magnetic field to produce torque.

If there is centrifugal switch and their is only one c.

Learn how a capacitor start induction run motor is capable of producing twice as much torque of a split phase motor.

A good rule of thumb is 50 to 100 of the total load.

The rotating magnetic field is easily achieved in three phase asynchronous motors because the phase angle offset between the individual phases is.